Product introduction:

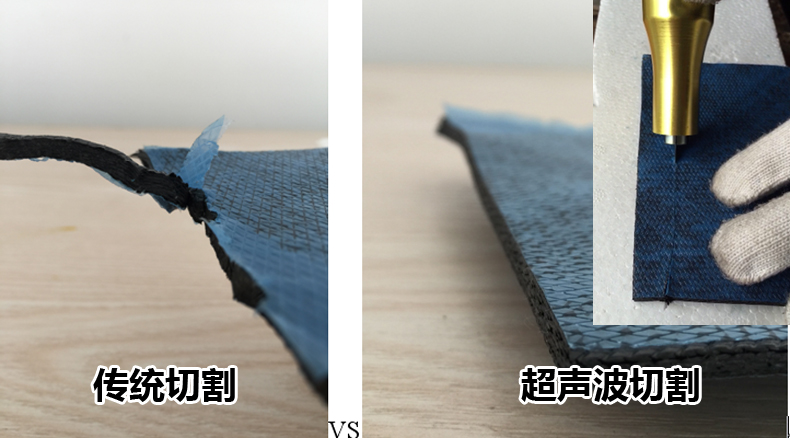

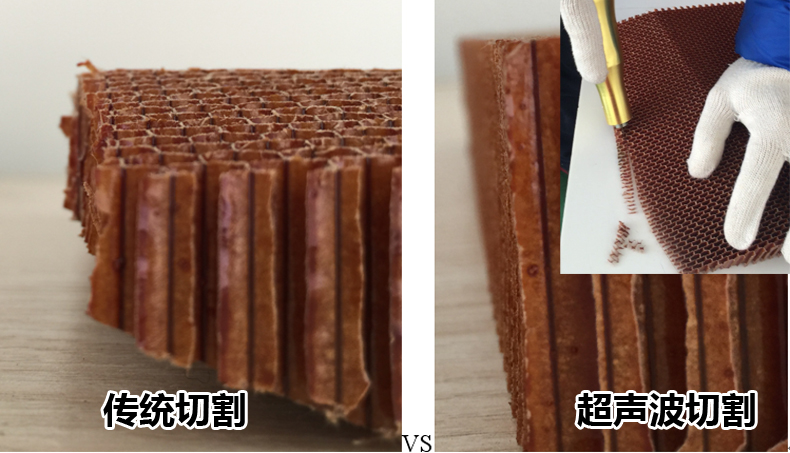

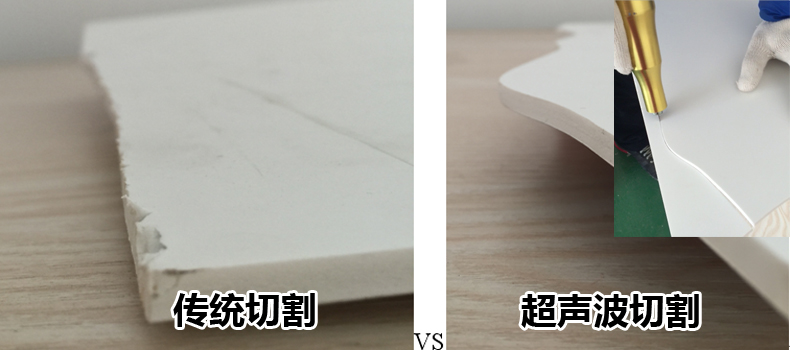

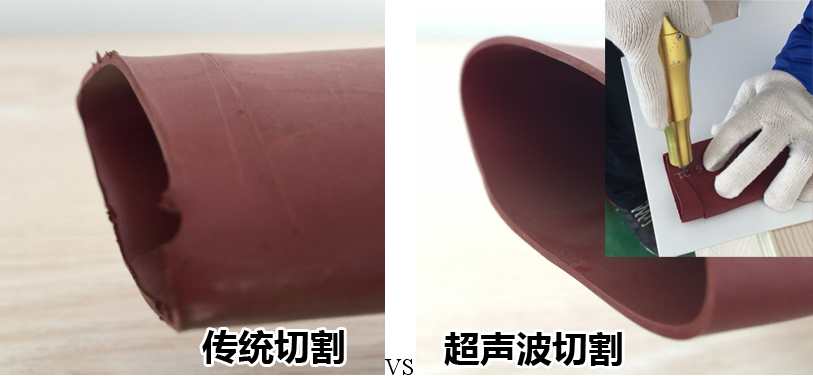

The ultrasonic cutting device is composed of an ultrasonic transducer, a shell, a tool head, a blade and a driving power supply. The ultrasonic wave produces energy with tens of millions of vibrations, cutting and gluing the cutting edge at the same time, so the cutting point will not produce edges or wear like conventional cutting, and the cutting edge will be very smooth. It can cut all kinds of ordinary cutting tools difficult to cut products, and solve the production and processing problems.

The ultrasonic cutting machine can be used not only by hand (for temporary cutting of a small amount of material), but also on the mechanical arm (suitable for mass production line cutting.)

Product model: BR-28C2

The main advantages:

1. cutting edge is very smooth and smooth

2. cutting efficiency is more than 10 times the traditional cost saving.

3. use compressed air device to ensure that the equipment can work stably for a long time.

4. special replaceable blade (wear-resistant), save money

5. simple operation, hand held cutting or CNC cutting.

Suggestion: use wood broken plate as a pad

Product specifications:

|

项 目

|

说 明

|

|

型 号

|

BR-28C2

|

|

超声波频率

|

28kHZ

|

|

切割力

|

200W

|

|

开 关

|

脚踏开关或外接控制

|

|

产品净重

|

4KGS

|

|

可选配电箱

|

100型模拟电箱

|

|

电 线

|

标准配2米,特殊长度需说明

|

The main application fields of the product:

Ultrasonic cutting equipment is specially suitable for cutting.

1. thermal plastics (plates, sheets, films, laminated materials)

2. carbon fiber CFRP

3. rubber (vulcanized latex, non vulcanized latex, film material, pipe)

4. composite materials (prepreg, polyethylene fiber, carbon molding products or glass fiber (GFRP))

5. resin

6. silica gel Silicone

7. food

8. foam

9. paper (honeycomb paper)

10.PVC foamed plate

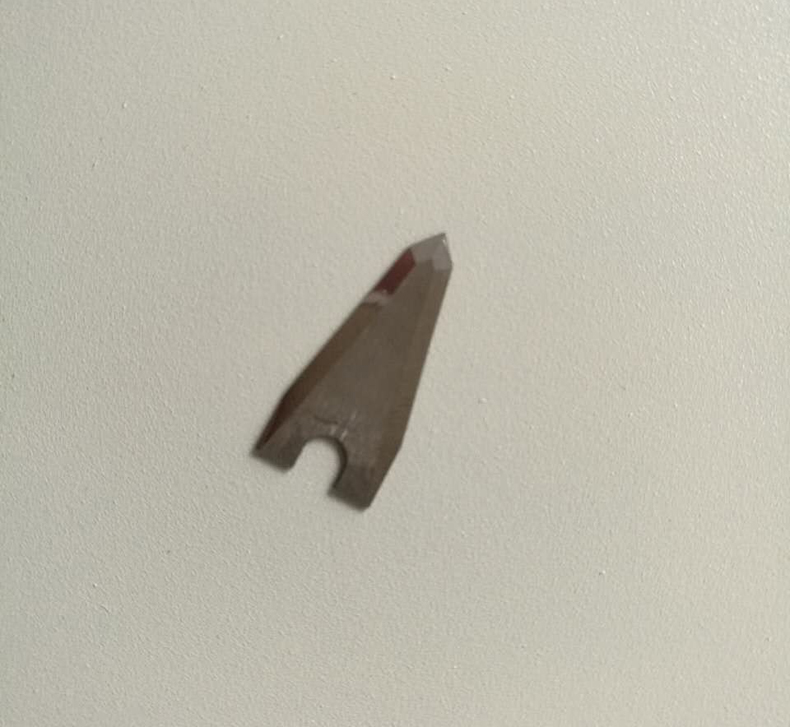

Ultrasonic cutting blade:

|