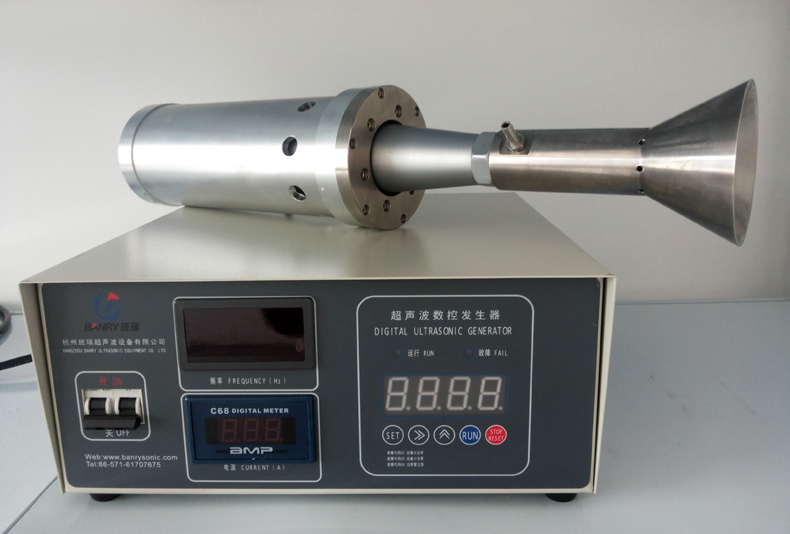

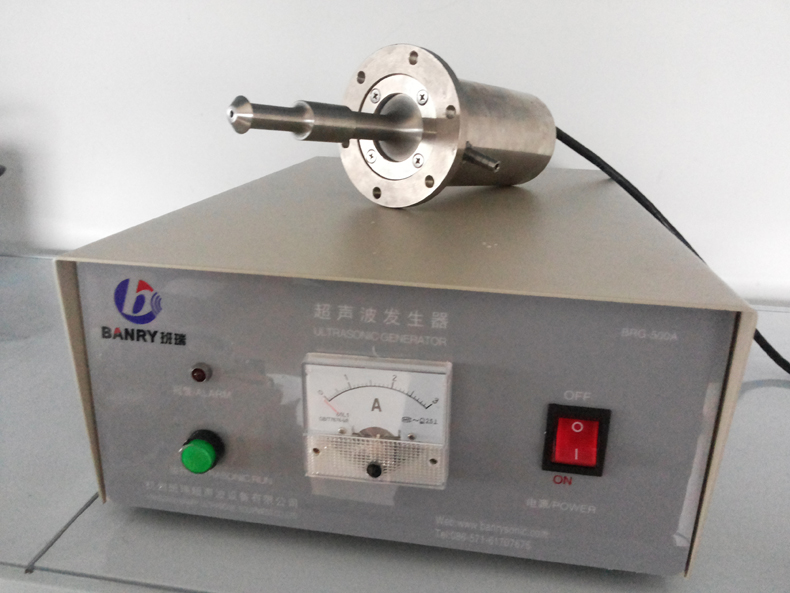

The ultrasonic atomizer is composed of an ultrasonic transducer, a case, an amplitude horn, an atomizing head and a driving power supply. Ultrasonic spray (atomization) is the use of the energy of ultrasonic energy to scatter water or liquid and form tiny particles of several m to more than 100 m. It is used for air humidification, liquid granulation, mixing, chemical reaction, spraying, metal melt making and so on.

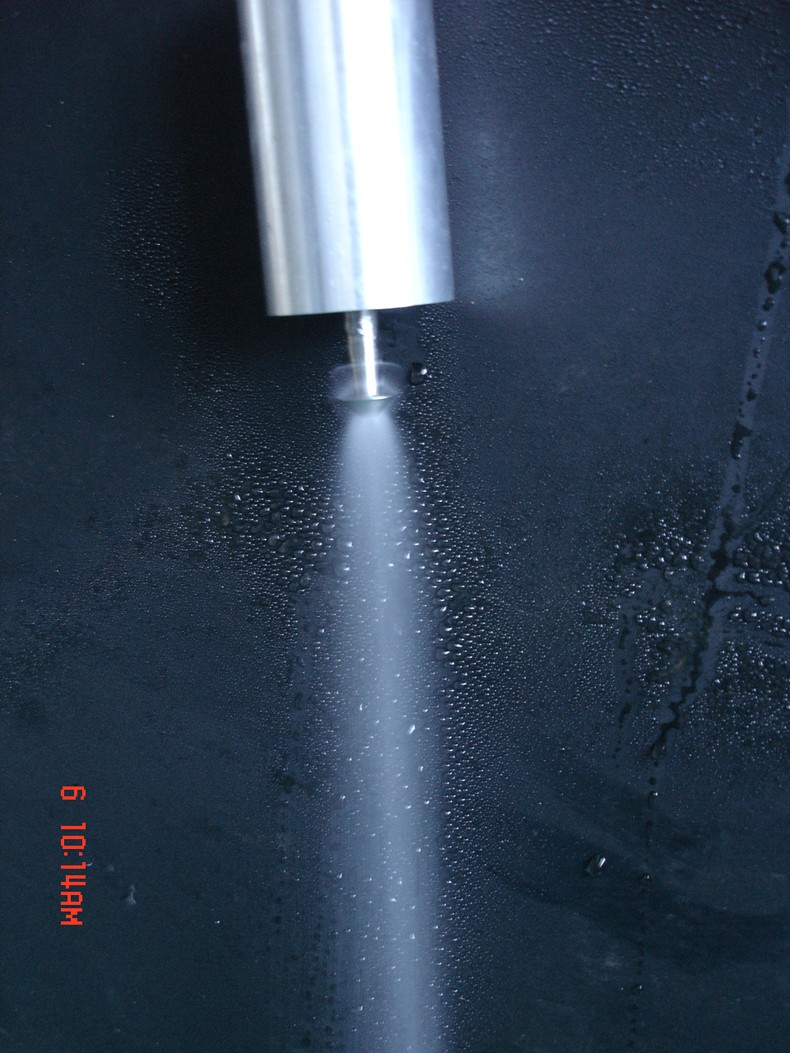

The power source of high power ultrasonic atomization and humidification is a high-power ultrasonic longitudinal transducer, which consists of an ultrasonic transducer, a horn, a launch head, and a special drive power supply. The transducer drives the launching head for high frequency vibration, exerts ultrasonic force on water or other liquid, and scatters the liquid into fine particles and sprays into the air to achieve the purpose of spray (atomization). It is characterized by low working frequency, high power, high atomization efficiency, a large atomization of a single transducer, a maximum atomization capacity of more than 100L/h, no restriction on medium, even the atomization of sewage, chemical liquid, and oil mucus. No pressure, no noise, no nozzle wear and blockage. The energy consumption is low, the single machine is small, and the atomizing volume can be adjusted at will, which is most suitable for application in the industrial field. By combination, the atomization quantity can meet any requirements of users.

The supersonic spray system has also been replaced by the traditional pressure spray system, which is widely used in various industrial processes and research and development. Especially in the field of micro coating spraying, the fog produced by the supersonic spray system is more accurate, easier to control and more environmentally friendly.

The ultrasonic spray (atomizer) also has a prominent advantage. It can work at a high temperature of several Baidu, and the maximum temperature is over 500 degrees Celsius. So it can be used for metal powder making, with simple process and high efficiency. Through different design of spray head, he can adapt to various requirements of flour milling. It is possible to achieve quick and simple milling from laboratory to a large number of industrial production lines.

Advantage:

1. great breakthrough in spray technology can atomization of various liquids.

2. power consumption is very low, fog is great, energy saving and environmental protection

3. no blockage, no wear, no noise, no pressure, no moving parts.

4. can be combined to achieve the required amount of spray.

5. manufacture of high performance titanium alloy and stainless steel

Product specifications:The main application fields of the product:

It is suitable for atomization and humidification, chemical mixing, production, spray drying granulation, paint spraying, metal powder making and so on.

|