Product introduction:

The ultrasonic emulsifying machine is composed of an ultrasonic transducer, a shell, an amplitude bar, a tool head (probe) and a driving power supply. The ultrasonic transducer is equipped with a fan to cool down, ensuring that it can work efficiently for a long time.

The advantages of phacoemulsification:

(1) the average droplet size of the emulsion formed is small and can be 0.2-2 mu m; the droplet size distribution is narrow, it can be 0.1-10 mu m, or the narrower concentration is higher, the concentration of pure emulsion can exceed 30%, and the added emulsifier can be as high as 70%.

(2) the emulsion formed is more stable. An important characteristic of ultrasonic emulsifying machine is that it can produce very stable emulsion without or without emulsifier.

(3) the type of emulsion can be controlled. Phacoemulsification, in some sound conditions, O/W (water oil) and W/O (oil water) type emulsion can be prepared, this is a mechanical emulsification method this is impossible to run. For example, toluene is emulsified in water and may form an emulsion under high acoustic intensity. Another type of emulsion can be formed under low sound and strong conditions, which means that only the properties of emulsifier can be used to control the type of the emulsion when the mechanical emulsification is used.

The obvious advantages of phacoemulsification have made it more and more applied in many industrial treatments, such as food, cosmetics, paper making, paint, chemical, chemical, pharmaceutical, textile, fuel and heat, fuel central air conditioning, petroleum, metallurgy, biodiesel and so on. Project.

Compared with the emulsifier, the phacoemulsifier has the advantages of good emulsifying quality, high production efficiency and low cost compared with the emulsifier, such as agitator, colloid mill and homogenizer. It has been paid more and more attention to and adopted by various industrial departments, and has become an important modern emulsifying equipment.

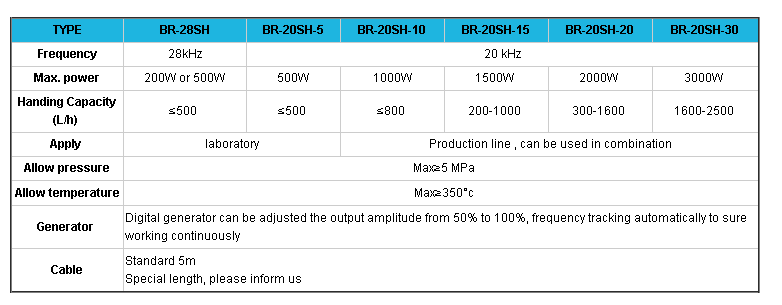

Product specifications:

The main application fields of the product:

It is suitable for food, cosmetics, paper making, paint, chemical industry, medicine, textile, fuel oil thermoelectricity, fuel oil central air conditioning, petroleum, metallurgy, biodiesel and so on.

1, Chinese medicine extraction, cell, bacteria, virus tissue fragmentation. For example, the extraction of a cells inclusions.

2. Dispersion and homogenization of material particles and emulsification of products. For example, the dispersion of nanomaterials, the emulsification of cosmetics.

3, accelerate dissolution and accelerate chemical reaction. For example, for chemical synthesis.

|